A research team led by Prof. WANG Mingtai at the Hefei Institutes of Physical Science of the Chinese Academy of Sciences has developed a finely tuned method for growing titanium dioxide nanorod arrays (TiO₂-NA) with controllable spacing—without changing individual rod size and demonstrated its application in high-performance solar cells.

Their findings, published in Small Methods, offer a new toolkit for crafting nanostructures across clean energy and optoelectronics.

Single-crystalline TiO₂ nanorods excel at harvesting light and conducting charge, making them ideal for solar cells, photocatalysts, and sensors. However, traditional fabrication methods link rod density, diameter, and length—if one parameter is adjusted, the others shift accordingly, often affecting device efficiency.

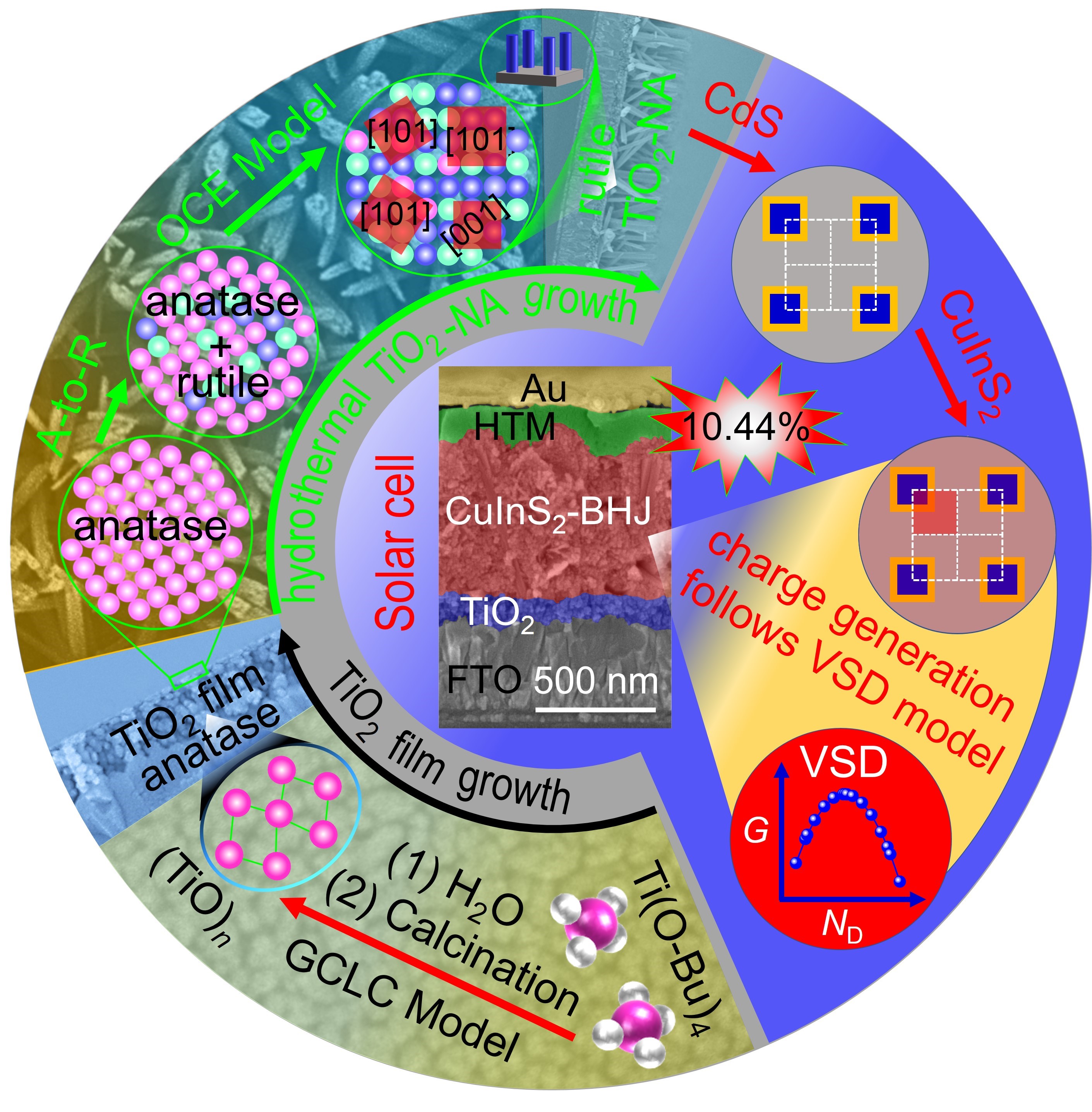

In this study, by carefully extending the hydrolysis stage of a precursor film, the team showed that longer "gel chains" assemble into smaller anatase nanoparticles. When the anatase film is subjected to hydrothermal treatment, those anatase nanoparticles convert in situ into rutile ones, serving as seeds for nanorod growth. The hydrolysis stage provides an effective way to control the rod density without altering the nanorod dimensions.

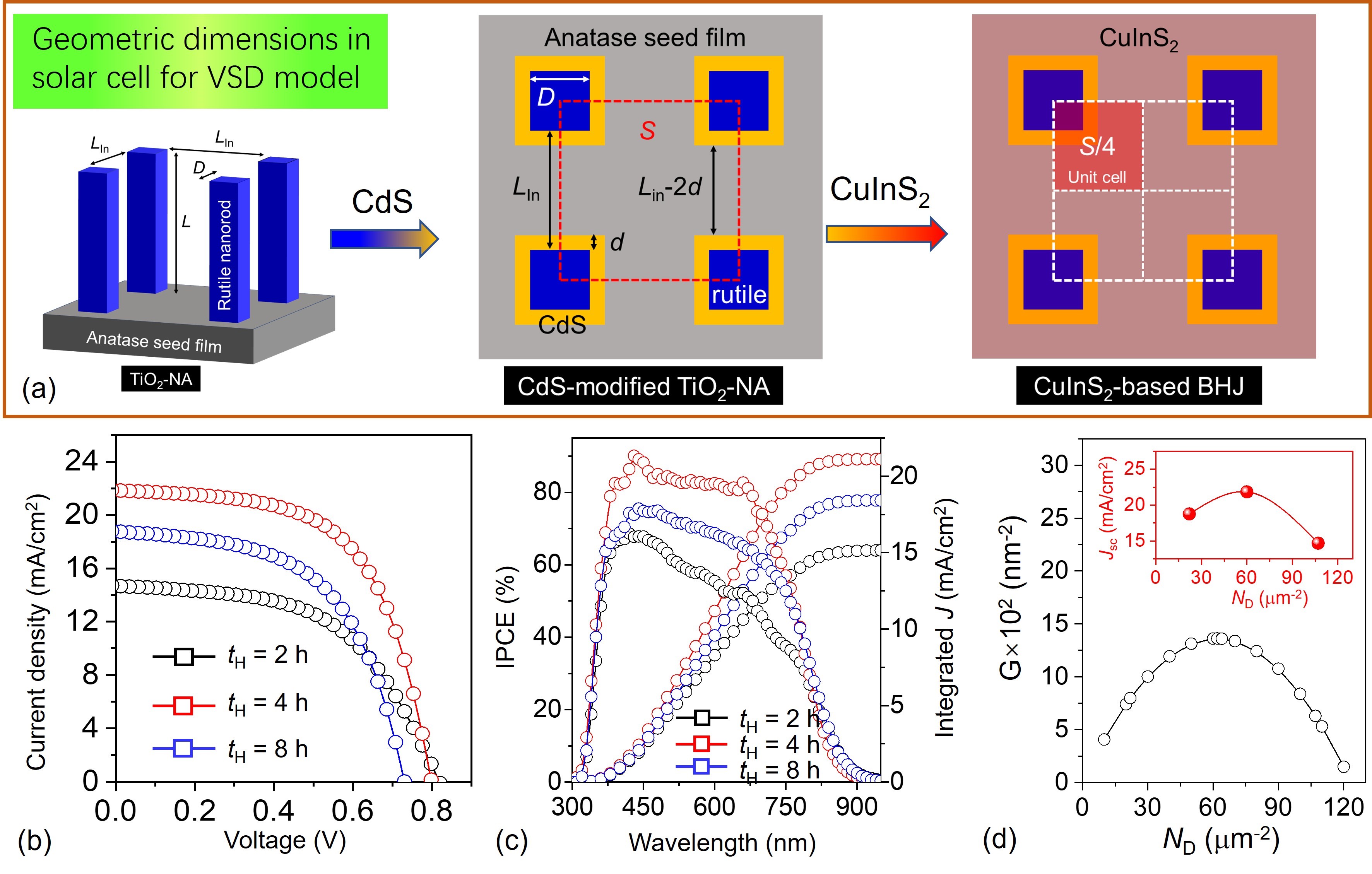

Using this strategy, they produced TiO₂-NA films with constant rod diameter and height, even as the number of rods per area varied. When incorporated into low-temperature-processed CuInS₂ solar cells, these films achieved power conversion efficiencies above 10%, peaking at 10.44 %. To explain why spacing matters so profoundly, the team introduced a Volume-Surface-Density model, clarifying how rod density influences light trapping, charge separation, and carrier collection.

This study overcomes the limitations of traditional methods for regulating nanostructures by establishing a complete system linking "macro-process regulation–microstructure evolution–device performance optimization."

Schematic illustration of the TiO2-NA preparation technology, growth principles, solar cell structure, and carrier generation model. (Image by CAO Wenbo)

Schematic diagram of VSD model. The performance of CuInS2 solar cells. (Image by CAO Wenbo)

86-10-68597521 (day)

86-10-68597289 (night)

52 Sanlihe Rd., Xicheng District,

Beijing, China (100864)