The Experimental Advanced Superconducting Tokamak (EAST) team proposed a new integrated control solution to tackle key problems in divertor power exhaust for the steady state operation of tokamak fusion reactor.

Through this new approach, the team, led by by XU Guosheng from the Institute of Plasma Physics, Hefei Institutes of Physical Science, achieved compatibility between high-performance grassy edge-localized mode (ELM) H-mode regime and feedback controlled radiative divertor.

In tokamak high-confinement operation, divertor and the first wall bear substantial steady-state and transient heat flux transported out from the core plasma, and the divertor is the component most strongly interacts with the plasma.

For future tokamak fusion reactors such as the International Thermonuclear Experimental Reactor (ITER), the steady-state heat flux onto the tungsten divertor surface must be kept below the engineering limit, i.e. ~10 MWm–2. Therefore partial detachment operation with impurity seeding or so-called radiative divertor has been considered as a primary solution for the ITER divertor heat flux control.

However, for the conventional ITER-like vertical-target-plate divertor, there is only a very small operational parameter window in which a partially-detached plasma can be maintained, which poses a great challenge for maintaining stable partial detachment with good plasma confinement for the high-performance steady-state operation of ITER.

Large transient heat flux known as ELMs can also bring great challenges to fusion reactor high-performance operation in addition to the unacceptable steady-state heat flux. Grassy ELM H-mode regime is an operational regime with good plasma confinement characterized by natural high-frequency small ELMs. Grassy ELM regime has been successfully achieved in EAST tokamak in a broad parameter space since 2016 campaign by XU and his colleagues.

The instantaneous heat flux produced by grassy ELMs is approximately 1/20th of that produced by conventional large Type-I ELMs. Notably (as shown in figure 1), grassy ELMs exhibits strong exhaust capability of tungsten impurity, making it an ideal candidate to compatibly operate with impurity seeding especially in a metal wall environment like ITER and the Chinese Fusion Engineering Test Reactor (CFETR).

Moreover, there is a relatively high plasma density at the tokamak separatrix in grassy ELM regime, which enhances boundary impurity screening and thus facilitates the achievement of detachment operation under radiative divertor.

Following the successfully establishment of grassy ELM regime in EAST, XU and his colleagues conducted a series of experiments in EAST facility to study the compatibility of grassy ELM regime with radiative divertor.

They found that significant degradation in plasma confinement usually occurs if the seeding impurities for radiative divertor are steadily injected without any control in grassy ELM regime.

Then they pushed their discovery further. Their following studies indicated that absolute extreme ultraviolet (AXUV) radiation signal near the tokamak X point is a good indicator of the plasma confinement during divertor impurity seeding, as the degradation of the confinement with excessive divertor impurity seeding/accumulation is usually correlated with significantly increased radiation near the X point.

However, controlling the AXUV radiation alone is insufficient to maintain the divertor in a partially detached state, as the absolute value of the AXUV radiation varies with plasma conditions during the detachment process.

To rise this challenge, the team this time developed a new feedback solution to actively control the detachment status of the ITER-like tungsten divertor in EAST.

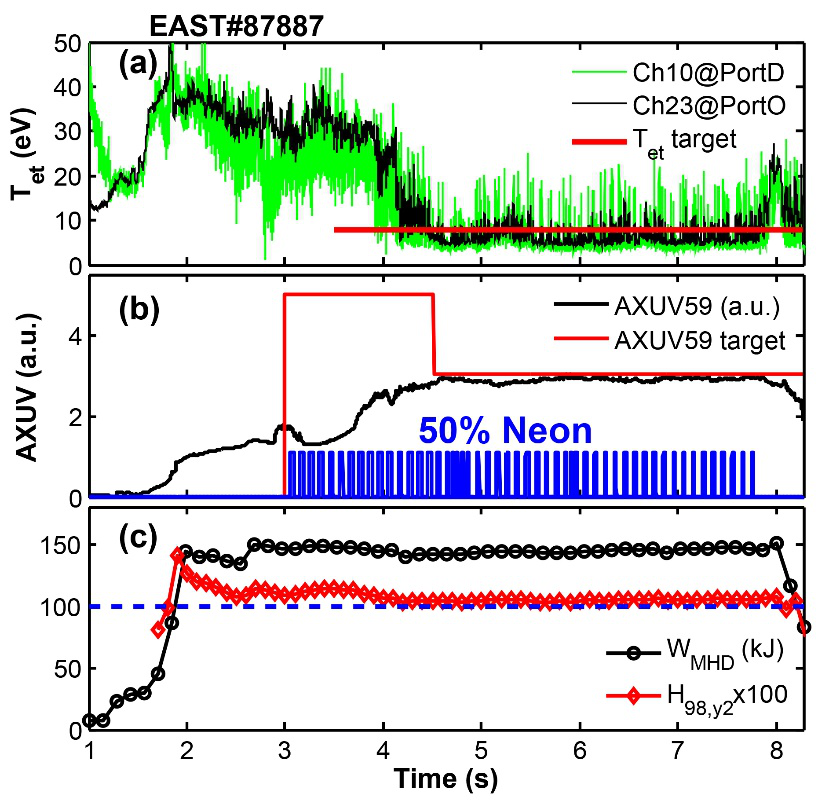

They firstly used a Langmuir probe to measure the electron temperature (Tet) near the divertor strike point to check the divertor status during grassy ELM discharges. Once the divertor detachment or partial detachment had been confirmed by i.e. Tetdropping below 5-8eV, the feedback control system would switch to an AXUV signal near the X-point then to actively control the divertor detachment.

The experimental results, as shown in figure 2, demonstrated that this control solution could realize steady partial detachment of the divertor target. The local peak temperature of the divertor target plate could be limited lower to 180℃ during the whole feedback process measured by an infrared camera.

Their experiment showed the control solution's success in realizing compatibility of partial detachment of the radiative divertor and high-performance grassy ELM regime.

In the future, according to the team, considering that the lower divertor of EAST is planned to be upgraded from current graphite to tungsten and will possess improved capabilities of power and particle exhaust, scientists will further optimize the integrated control solution towards the potential applications on future fusion reactors, and thus facilitate their steady-state operations.

Works described above were enabled by the cooperation of the EAST team and international collaborations, and are supported by grants including the National Key R&D Program of China, the National Natural Science Foundation of China and the Key Research Program of Frontier Sciences of the Chinese Academy of Sciences.

Fig.1. Good tungsten exhaust capability of grassy ELM regime compared with large Type-I ELM regime (Image by EAST Team)

Fig.2. EAST steady-state grassy-ELM H-mode and radiative divertor compatibility operation discharge (Image by EAST Team)

86-10-68597521 (day)

86-10-68597289 (night)

52 Sanlihe Rd., Xicheng District,

Beijing, China (100864)