Scintillator can absorb high-energy particles and emit low-energy photons, and has been applied in many high energy physics (HEP) experiments. As the core material of electromagnetic calorimeters, the performance of scintillators will greatly affect the detection efficiency.

In order to meet the requirements of HEP experiments, scintillators should have high density, fast decay time, good radiation damage resistance, and small slow component contamination. Lu3Al5O12:Ce (LuAG:Ce) is a very competitive scintillator with high density, fast scintillation decay time and high theoretical light yield (LY).

Further, the light yield and transmittance of LuAG:Ce ceramic remain almost unchanged after 220 Mrad gamma-ray radiation, indicating that the Ce3+ activated LuAG ceramic is a promising material for HEP experiments. However, some defects in LuAG:Ce scintillators, such as anti-site defects, are the main reasons for the slow component, which have largely limited the performance of scintillator.

Recently, a research team led by Prof. ZHANG Long from Shanghai Institute of Optics and Fine Mechanics of the Chinese Academy of Sciences has successfully fabricated a fast Ce3+ and Ca2+ co-doped LuAG scintillation ceramic by traditional solid-state reaction method. The result was published on Journal of Luminescence.

In the experiment, the ceramics were sintered at a temperature higher than 1800 °C for 12-18h in vacuum atmosphere; and oxygen-annealing treatment was applied to the ceramics to eliminate oxygen vacancies.

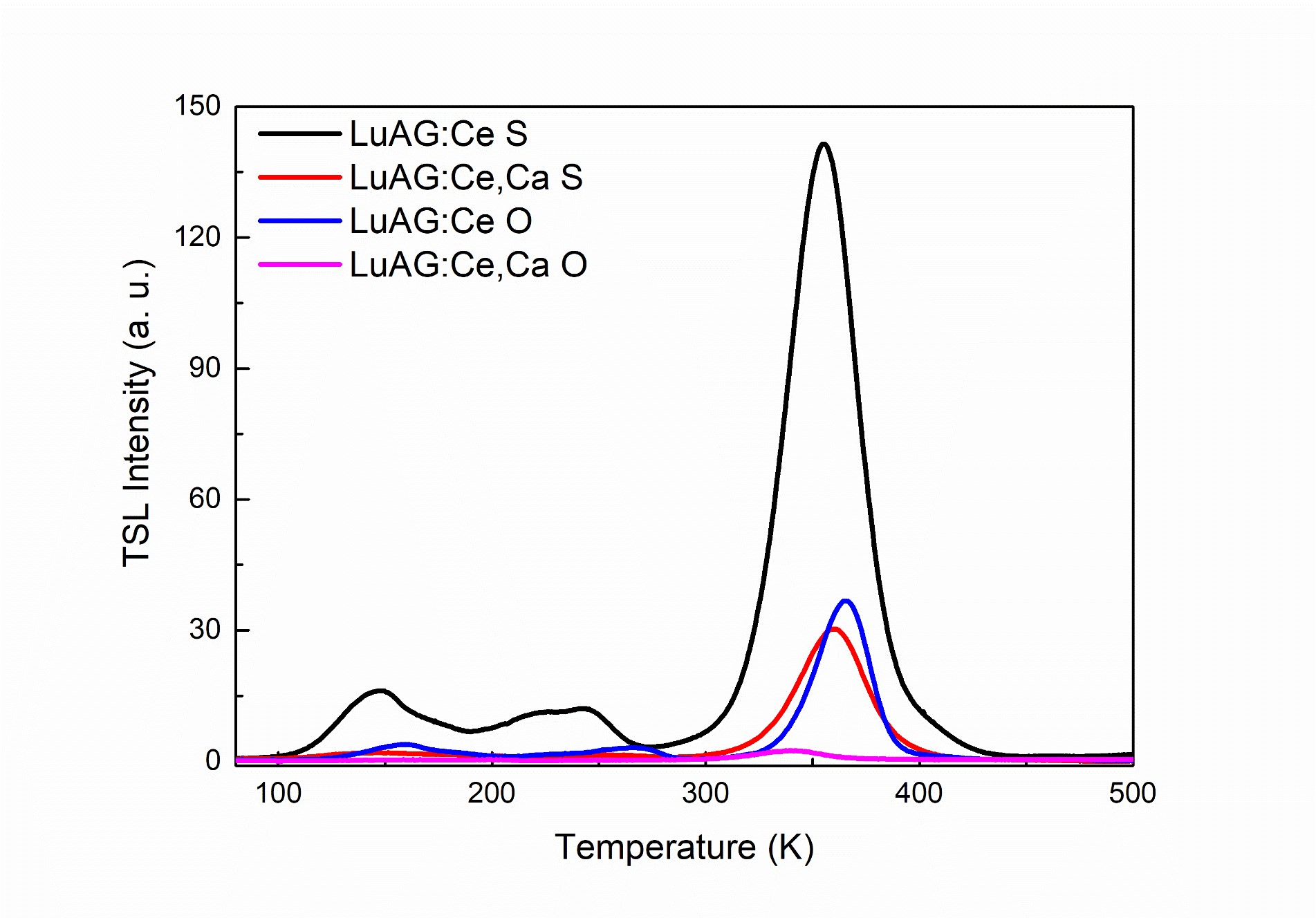

In addition, it could be told from the thermally stimulated luminescence (TSL) spectra that both the Ca2+ co-doping and oxygen- annealing treatment could reduce the TSL intensity, which meant that the negative effect of defects was enormously reduced.

With the combination of Ca2+ co-doping and oxygen-annealing treatment, the scintillation performance of LuAG:Ce,Ca ceramic was significantly improved.

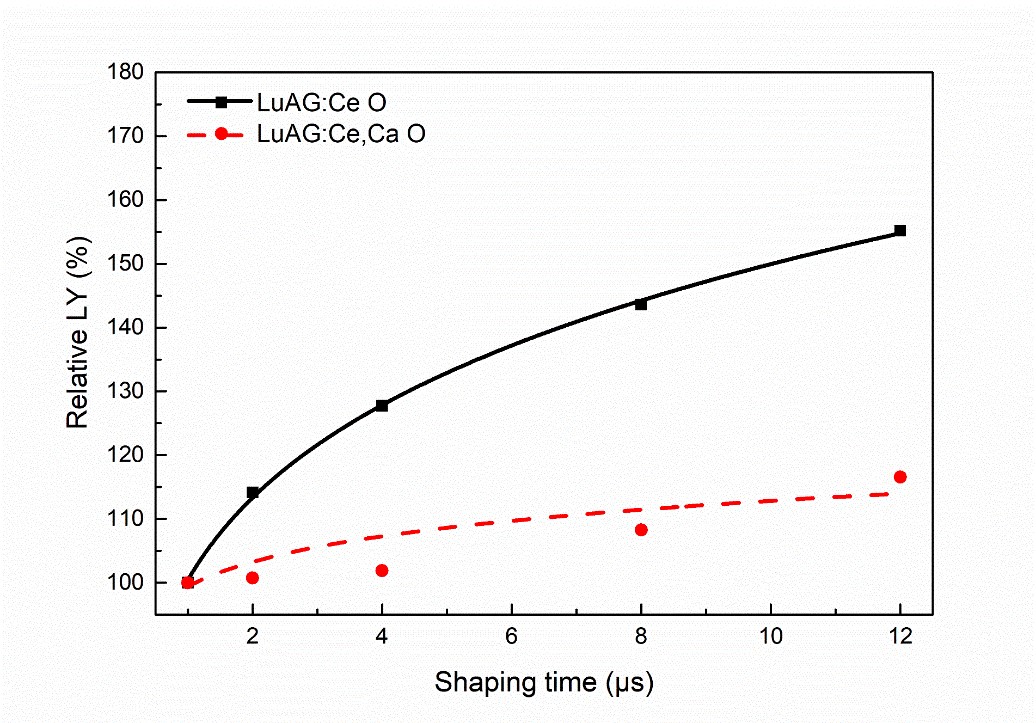

When using a short shaping time of 1 μs, the light yield of Ca2+ co-doped ceramic was as high as 24,100 ph/MeV, while the light yield value of the unco-doped one was 13,100 ph/MeV. The fast-to-slow ratio calculated as (LY (1 μs)/LY (12 μs)) of the two ceramics were 85.5% and 69.3%, respectively, indicating a much smaller slow component contamination in the LuAG:Ce,Ca ceramic.

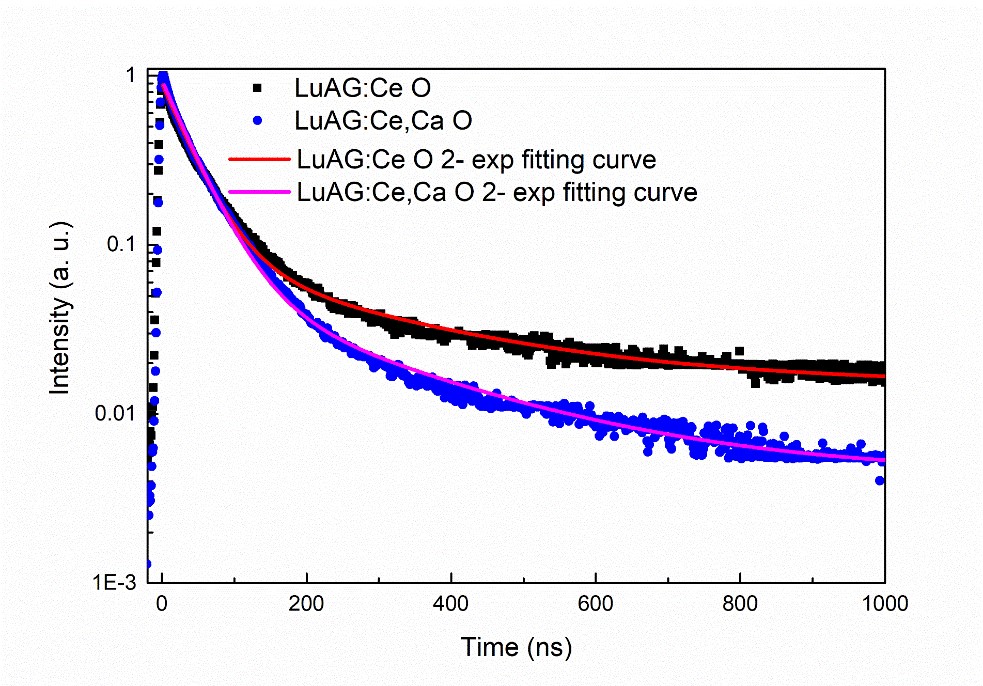

The scintillation decay of Ca2+ ions co-doped ceramic has a fast component of about 42 ns and the slow component is also faster than the unco-doped one.

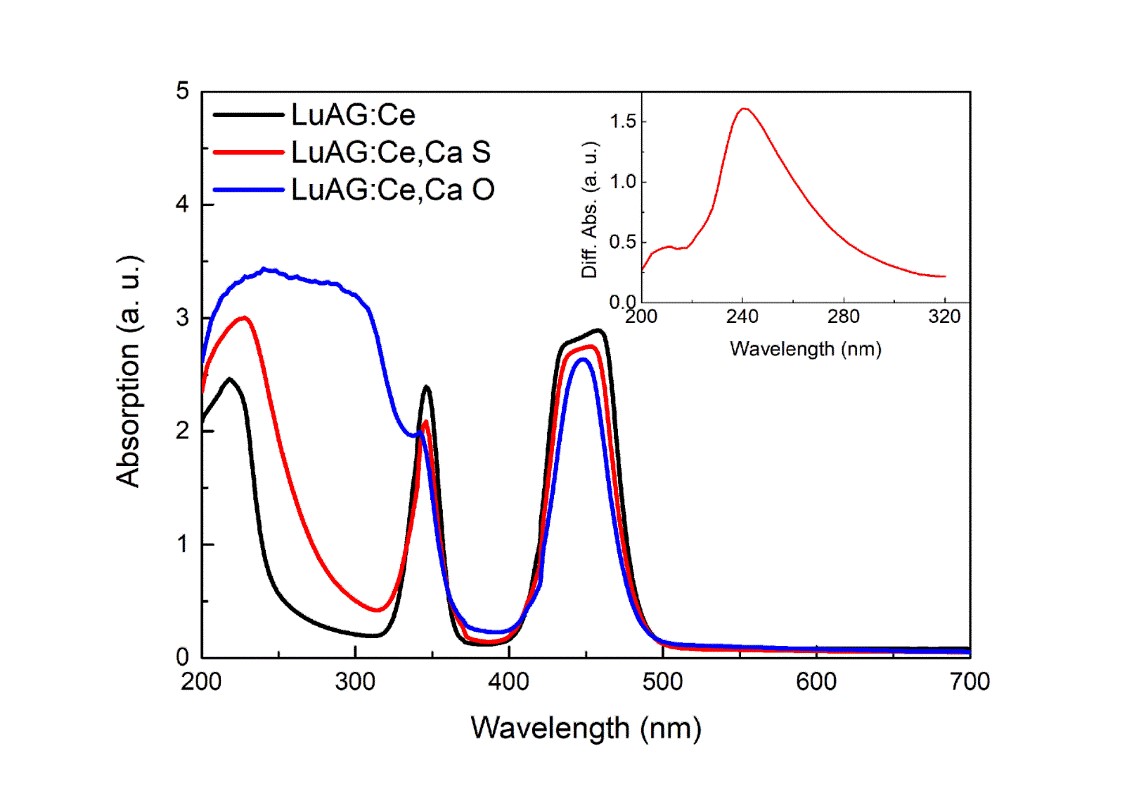

Absorption spectra of the prepared LuAG:Ce and LuAG:Ce,Ca ceramics before and after annealing. (Image by SIOM)

TSL curves of LuAG:Ce and LuAG:Ce,Ca ceramics before and after oxygen-annealing. (Image by SIOM)

Relative light yield of the annealed LuAG:Ce and LuAG:Ce,Ca ceramics at different shaping time from 1 μs to 12 μs. (Image by SIOM)

Decay curves of oxygen-annealed LuAG:Ce and LuAG:Ce,Ca ceramics (Image by SIOM)

86-10-68597521 (day)

86-10-68597289 (night)

52 Sanlihe Rd., Xicheng District,

Beijing, China (100864)