Newsroom

A research team from the Xinjiang Technical Institute of Physics and Chemistry of the Chinese Academy of Sciences, has developed a basalt fiber/cotton fiber composite yarn that integrates weavability with multiple functional properties. The study was recently published in Composites Communications.

The textile industry is a major contributor to global resource consumption and environmental pollution. The researchers noted that approximately 85% of textiles ultimately end up in landfills. Its production process accounts for roughly 5% to 10% of global greenhouse gas emissions, in addition to substantial water consumption and the release of chemical pollutants.

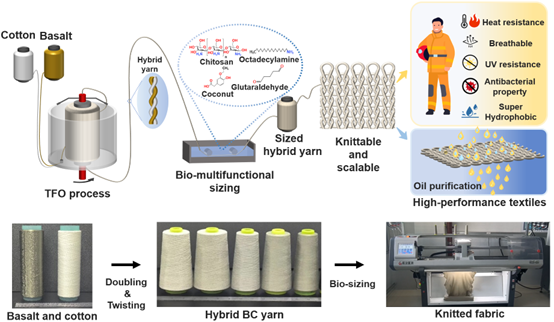

To align with the United Nations Sustainable Development Goals and promote green materials and clean production, the team combined basalt fibers with natural cotton fibers. Leveraging "Twist-for-one (TFO)" technology and a self-developed, fully natural sizing agent, they created a novel composite yarn that is both high-performing and environmentally friendly.

The sizing agent is primarily composed of natural materials such as chitosan and coconut oil. Test results indicate the composite yarn boasts a strength of 59.6 cN/Tex, outperforming ordinary cotton yarn (14.0 cN/Tex). Fabrics woven from this yarn exhibit multiple functional properties: a surface water contact angle of 152.4°, demonstrating hydrophobicity and resistance to penetration by liquids; an ultraviolet protection factor (UPF) of up to 265.3, exceeding daily protection standards; and antibacterial rates of 99.1% and 97.1% against Staphylococcus aureus and Escherichia coli, respectively. Additionally, the fabric shows enhanced thermal stability, with an initial thermal decomposition temperature approximately 40 °C higher than that of pure cotton fabric.

The material holds application potential in fields such as specialized protective clothing, high-performance sportswear and outdoor functional apparel. The study validated the entire process—from yarn preparation and sizing treatment to weaving—using industrial-grade equipment, demonstrating the feasibility of large-scale production and laying a foundation for subsequent industrialization.

"This work is not only an exploration of a new material but also an important practice in advancing the textile industry's sustainable development pathway," said Prof. Ma Pengcheng, corresponding author of the study.

The research was supported by the Xinjiang Tianchi Talent Program for Introducing Innovation Leaders and the CAS Western Light Program, among other funding sources.

Schematic diagram showing the experimental design and developed hybrid yarns and fabrics. (Image by Prof. MA Pengcheng's team)