Functional Carbon Materials Research Group at the Ningbo Institute of Materials Technology and Engineering of the Chinese Academy of Sciences, in cooperation with researchers from the University of Nevada, developed a graphene thermal interface material (TIM) composed of mainly vertically aligned graphene.

Thanks to the ultra-high through-plane thermal conductivity and low compressive modulus, the resultant graphene TIM may satisfy the demanding heat dissipation requirements for next-generation high-power integrated circuits (ICs). The study was published in ACS Nano.

With the prosperous technology evolution for miniaturization and dense integration of semiconductor devices, the heat transfer problem has drawn great concern. Statistics indicated that a 10 – 15 °C temperature rise in electronic components may lead to a 50% reduction in the device's lifespan. Therefore, heat transfer in electronics has become the primary issue hampering the performance and shortening the lifespan.

As an efficient method to address this issue, TIMs are applied to fill the microgaps and bridge between the heat generating components and the sink/spreader. They are desired to have both high through-plane thermal conductivity and high compressibility, which are difficult to satisfy simultaneously for most materials, like hard metals and soft silicones.

To address this problem, the researchers developed a soft graphene TIM with a low compressive modulus of 0.87 Mpa, much smaller than that of silicone-based composites (2 – 10 MPa), and an ultrahigh through-plane thermal conductivity of 143 W m-1 K-1 , a thousand times as high as the silicones and exceeding that of many metals.

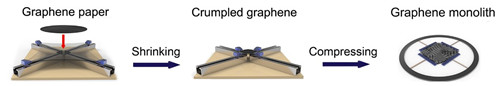

The samples were made by a feasible machining-based process based on a self-developed automation equipment, which manipulated the stacked architecture of graphene paper from horizontal to vertical orientation. The obtained graphene TIM showed a hierarchical microstructure composed of mainly vertically aligned graphene in the middle, and a thin cap of horizontal graphene layers at both top and bottom sides.

According to the TIM performance measurement, the system cooling efficiency with the graphene as TIM was ~3 times as high as that of state-of-the-art commercial thermal pads (~17 W m-1 K-1), with a decrease of the heater temperature by 65 °C (the samples) versus 38 °C (counterparts), indicating a significant improvement in the heat dissipation capacity of electronics.

Moreover, due to the all-inorganic composition of graphene, the obtained graphene TIM showed an excellent thermal cycling stability (< 0.5% decay after 2,500 cycles) and a wide operating temperature range in air (-196 – 500 °C), which were both far beyond those of silicone-based thermal pads (-50 – 200 °C), suggesting potential heat transfer applications in extreme environments.

This technical breakthrough not only provided an efficient and scalable method for the development of graphene sheets with superlative thermal transfer properties, but also offered novel insight into the construction of others two-dimensional materials (e.g., BN nanosheets and Mxenes) and vertically aligned architectures, as well as the extension of their real-world applications.

Schematic illustration presenting the fabrication process of graphene monolith from graphene paper. (Image by DAI Wen)

86-10-68597521 (day)

86-10-68597289 (night)

86-10-68511095 (day)

86-10-68512458 (night)

cas_en@cas.cn

52 Sanlihe Rd., Xicheng District,

Beijing, China (100864)